- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Size: | |

|---|---|

| Availability: | |

| Quantity: | |

PSW-4500

EAGLE

8477

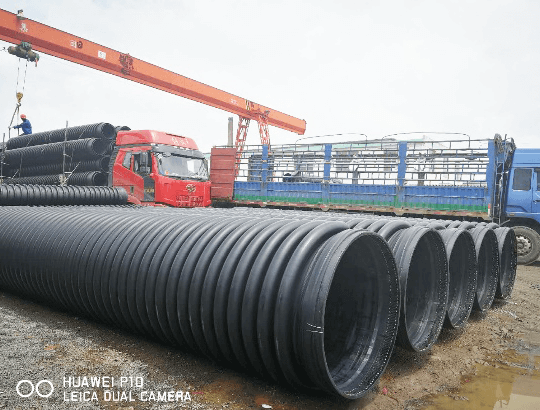

The HDPE spiral wound pipe extrusion machine can produce the HDPE spiral wound pipe and fittings, HDPE spiral manhole from DN/ID300mm to DN/ID 4500mm. The main applications for the final HDPE spiral wound pipes are non-pressure applications, such as drainage system, storm water outfall pipe, sewerage pipe, storm water rentation tank, marine structured wall pipe and chemical storage tanks as well as low-pressure applications like irrigation systems,etc.

The great advantage of HDPE spiral wound pipe extrusion machine is that production is very flexible. One HDPE spiral corrugated pipe extrusion machine can produce the HDPE spiral wound pipe from DN300 to DN4500 with very short changing time for the production from DN300 to DN4500mm. It also can produce different types and ring stiffness classes HDPE spiral corrugated pipe from SN2 to SN32, according to ISO9969, DIN16961.

· HDPE spiral corrugated pipe diameters: DN/ID 300 mm up to DN/ID 4500 mm

· HDPE spiral wound pipes length: 6 to 9 m, with integrated socket and spigot or according to customer's requirement.

· Material: High density Polyethylene, Polypropylene (PP-HM, PP-B, PP-H)

· Output: 700-1400kg/h

· Application: Drainage Pipe systems, Sewage pipe systems, Industrial pipes, Relining, Outfall pipes, chemical tank, marine structured wall pipe, storm water rentention tank

Krah pi

Krah production technology is a helical extrusion (spiral wound)

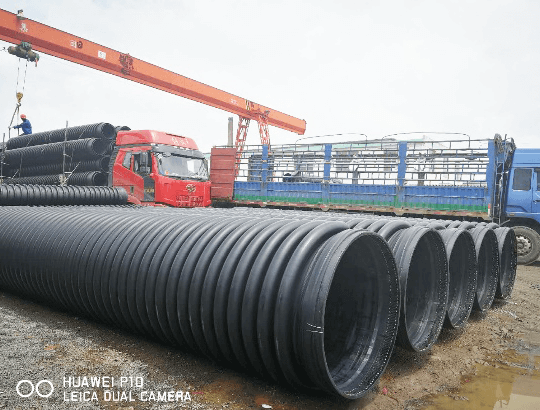

The HDPE spiral wound pipe extrusion machine can produce the HDPE spiral wound pipe and fittings, HDPE spiral manhole from DN/ID300mm to DN/ID 4500mm. The main applications for the final HDPE spiral wound pipes are non-pressure applications, such as drainage system, storm water outfall pipe, sewerage pipe, storm water rentation tank, marine structured wall pipe and chemical storage tanks as well as low-pressure applications like irrigation systems,etc.

The great advantage of HDPE spiral wound pipe extrusion machine is that production is very flexible. One HDPE spiral corrugated pipe extrusion machine can produce the HDPE spiral wound pipe from DN300 to DN4500 with very short changing time for the production from DN300 to DN4500mm. It also can produce different types and ring stiffness classes HDPE spiral corrugated pipe from SN2 to SN32, according to ISO9969, DIN16961.

· HDPE spiral corrugated pipe diameters: DN/ID 300 mm up to DN/ID 4500 mm

· HDPE spiral wound pipes length: 6 to 9 m, with integrated socket and spigot or according to customer's requirement.

· Material: High density Polyethylene, Polypropylene (PP-HM, PP-B, PP-H)

· Output: 700-1400kg/h

· Application: Drainage Pipe systems, Sewage pipe systems, Industrial pipes, Relining, Outfall pipes, chemical tank, marine structured wall pipe, storm water rentention tank

Krah pi

Krah production technology is a helical extrusion (spiral wound)